- Meat industry experts, analysts and a union that represents meatpacking plant workers say challenges with the country’s meat supply chain will likely linger as long as the pandemic does.

- Kroger, Costco and other grocery stores are restricting how much meat customers can buy at a time.

- Limited supply of fresh beef means Wendy’s restaurants across the country are taking hamburgers off their online menus.

On trips to the grocery store and the fast food drive-thru, customers have yet another reminder of how the coronavirus pandemic has disrupted their routine: Emptier than usual meat aisles. Butcher counters without the usual variety. And hamburgers that are harder to come by.

In meatpacking plants from South Dakota to Tennessee, workers have gotten sick from the coronavirus as they work side-by-side cutting, boning and trimming meat. The spread has shuttered plants, slowed production and created a ripple effect across the supply chain.

Farmers and ranchers have hogs, cattle and chicken that they feed, but can’t sell. Meatpacking plants don’t have enough workers as they get sick and have heightened anxiety. And grocery shoppers and restaurants can’t get their typical cuts or supply of meat.

Major grocers, including Kroger and Costco, added purchase limits this week for meat to prevent hoarding and help keep it in stock. Nearly a fifth of Wendy’s U.S. restaurants removed hamburgers and other beef products from their online menus, according to Stephens Inc. And another chain, Shake Shack, said rising beef prices have taken a bite into its profits.

Industry experts, analysts and a union that represents meatpacking plant workers say challenges with the country’s meat supply chain will likely linger as long as the pandemic does.

“What we’re seeing is an imbalance between production and consumption, which is causing disruption throughout the entire value chain,” said Patrick Stover, dean of Texas A&M University’s College of Agriculture and Life Sciences and director of Texas A&M AgriLife Research.

Sick workers, shuttered factories

Tyson Foods, the country’s largest meat processor, fired a warning shot about problems with the meat supply chain in late April. The company’s chairman, John Tyson, took out a full-page ad in some of the country’s most-read newspapers, saying “the food supply chain is breaking.”

In the ad, Tyson warned “there will be limited supply of our products available in grocery stores until we are able to reopen our facilities that are currently closed.”

Some of Tyson facilities — including its largest pork plant — have been shuttered as workers have gotten sick and some have died. One of the largest U.S. pork producers, Smithfield Foods, has also closed large facilities because of outbreaks.

Days after the ad ran, President Donald Trump declared meat processing plants “critical infrastructure” to try to keep them open. The move was applauded by meat industry leaders, who said it would accelerate production, and criticized by unions who said it did little to improve safety and protect workers.

But plants have continued to close and struggle to operate at full capacity.

Tyson, for example, said Thursday that its largest pork plant would reopen in Iowa. In a news release, though, it said the plant would “resume limited production.” The company said it added new safety measures, including temperature checks, an on-site clinic for Covid-19 testing and social distancing of workers.

Mark Lauritsen, head of the food processing, packing and manufacturing division of the United Food and Commercial Workers, said meatpacking plants will continue to produce less meat for grocery stores and restaurants during the pandemic. The union represents about 250,000 food processing and meatpacking workers across the U.S. and Canada.

He said plants will produce less as workers get sick and factories shut down or they will adapt the process to prevent further outbreaks through social distancing. Either way, he said, there’s decreased supply.

“During this time of Covid-19, we have to spread people out and if we spread people out, that means less production,” he said. “If we don’t do it, we’re just going to continue in this cycle of a plant running at half speed for two weeks and then having to close down for two weeks.”

To strengthen the supply chain, he said the government should expand workers’ access to rapid testing for Covid-19 and ramp up production of high-quality masks for them, such as N95 or A100 respirators.

“Until the world gets its arms around coronavirus, this is the model we’re going to have to work under — or we’re going to sacrifice these humans for the sake of a cheeseburger,” he said.

Cooking more, eating out less

As people stay at home during the pandemic, they’re loading up their grocery baskets, cooking at home and avoiding restaurants. All of those behavior changes have challenged the supply chain, too.

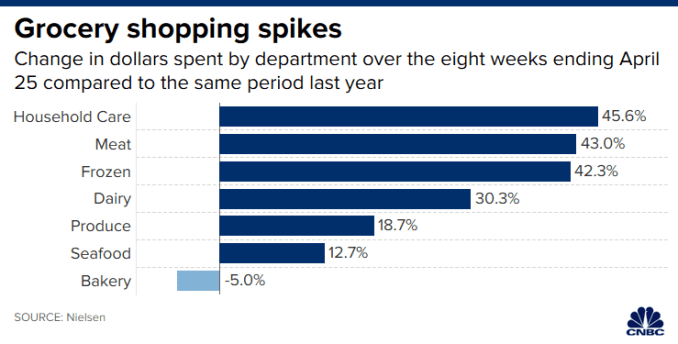

Even before the closures of meatpacking plants, demand for meat rose as many customers stocked up on groceries. In the eight-week period that ended April 25, meat sales at grocery stores and other retailers were up 43% compared to the same period last year, according to Nielsen data.

Meat sales increased at a higher rate than any other department during that 8-week period, except household care, the category that includes toilet paper, paper towels and cleaning products, Nielsen data showed.

People also want different cuts of meat when they’re doing the cooking, Stover of Texas A&M said. For example, he said, chicken wings are typically eaten at restaurants instead of cooked at home, so demand has dropped during the pandemic.

“They don’t eat the same thing in restaurants that they eat when they are going to cook for themselves,” he said.

That’s eventually felt back at the plants, as workers and companies that typically process meat for restaurants produce kinds of meat that customers aren’t looking for at the grocery store.

“It’s complicated,” he said. “Just because you can move chicken wings from the restaurant to the grocery store doesn’t mean people are going to cook them.”

Kroger CEO Rodney McMullen told CNBC that the grocery chain is trying to divert meat that would typically go to restaurants and work with new suppliers. He said stores have a supply of meat, but customers may not find the typical variety.

“If you’re flexible on eating between chicken, pork and beef, we constantly have one of those items or two of those — and usually three,” he said.

Industry analyst Heather Jones said that some meat products will be easier to find than others. Steak, for example, will be in ample supply as fine-dining restaurant sales continue to plummet.

On the other hand, more highly-processed meats popular for cooking may be harder to find, she said. Whole chickens might replace thighs, drumsticks and breasts in grocery stores because meat processors don’t have the workers to cut up the birds. Ground beef may be in shorter supply as processors struggle to slaughter enough cattle to keep up with demand, said Jones, who runs Heather Jones Research.

Other pressures on the supply chain

As production lags, meat processors are struggling to divert products meant for hotels, schools and restaurants to grocery stores. The U.S. Department of Agriculture has relaxed its labeling requirements for meat in an effort to make the process easier.

Still, Tyson Chief Financial Officer Stewart Glendinning told CNBC that not all of the company’s plants can be switched over to process meat for grocery stores. To shift capacity to retail, Tyson had to adjust manufacturing lines by adding a piece of equipment and swapping out clear plastic film for printed packaging.

Smaller meat producers that typically only supply restaurants might not have relationships with grocery stores and lack a middleman to connect the two, Jones said.

Restaurants’ meat supply may be squeezed as meat processors scramble to meet grocery demand. In a research note, Stifel analyst Chris O’Cull said he spoke to food distribution industry sources who said grocery store orders are being prioritized ahead of restaurant orders.

Wendy’s is already facing fresh beef shortages in many of its restaurants. The burger chain, which has long touted its use of fresh beef as a way to differentiate from the competition, has pivoted its marketing to focus on chicken products.

“It is widely known that beef suppliers across North America are currently facing production challenges,” Wendy’s spokeswoman Heidi Schauer said in a statement to CNBC. “We continue to supply hamburgers to all of our restaurants, with deliveries two or three times a week, which is consistent with normal delivery schedules. However, some of our menu items may be temporarily limited at some restaurants in this current environment.”

As plants process less beef and pork, it’s created a bottleneck for farmers and ranchers who have squeezed profits. Some are euthanizing healthy livestock to reduce herd sizes.

Jones said that could create problems, even as meat processing plants reopen and are able to resume typical capacity. She said reduced pork production could continue into the first half of 2021.

Stover said Texas A&M’s agriculture program is educating farmers and ranchers on how they get financial assistance to keep them afloat.

“If they can’t move food today, they can’t start the preparation, the planting and the breeding for the food that’s going to be needed months from now,” he said. “You’re seeing this sort of back-up in the system that will have long-term consequences, if we don’t pay attention right now to assuring stability in the production system and ensuring that farmers and ranchers can continue to run their operations and produce the food for consumers.”

Otherwise, he said, that could become another broken link in the meat supply chain.